Author: Tina Thomas (FhG IZM)

Exhibition at PCIM

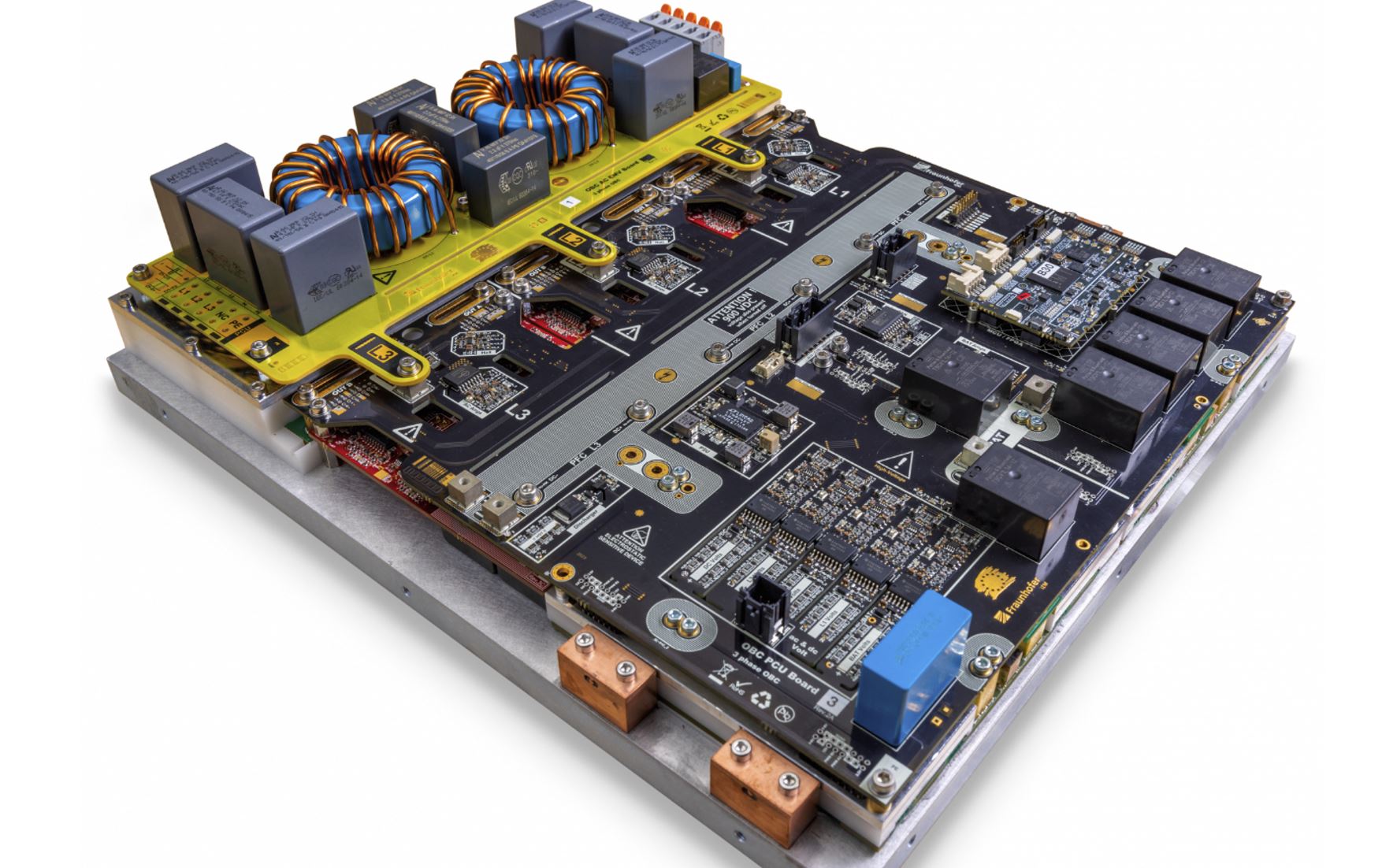

In the recent ‘Power Conversion and Intelligent Motion (PCIM)’ event held from May 6-8th, 2024 in Nuremberg, Germany, Energy ECS ‘s German partner, Fraunhofer IZM, presented the developed power electronics unit for the On-Board Charger of UC4.

Charging on public AC grids is a challenge for e-mobility. Fraunhofer IZM has now succeeded in combining the latest achievements in the field of power electronics for the next generation of On Board Chargers. Bidirectional charging processes of up to 22 kW are made possible by pioneering PCB and packaging solutions that also enable automated production. One of the two key newly developed components is the sine-amplitude converter (SAC), which utilizes innovative wide-bandgap semiconductors based on gallium nitride (GaN). The new GaN switches make it possible to clock the resonant transformer – with an LLC topology – at 1 MHz and higher.

The other of the two essential components is the power factor correction converter (PFC) – a bulky component with high production costs in previous OBCs, particularly due to the chokes required. At Fraunhofer IZM, planar PFC chokes have been developed on a PCB basis, with four magnetically coupled windings on a common ferrite core. The flat design not only saves space, but is also associated with very short cooling paths.

Fraunhofer IZM’s research in UC4 sets new standards miniaturized power electronics by downsizing the volume of common OBC to roughly 50% and keeping the production cost low by enabling automatic assembly. The presented power electronics unit was a real crowd-puller, inspiring the community to drive miniaturization forward.

Tutorial at ECCE:

In the recent ‘Energy Conversion Congress & Expo (ECCE)’ event held from September 2nd – 6th, 2024 in Darmstadt, Germany, Energy ECS ‘s German partner, Fraunhofer IZM, held a half-day tutorial “Planar Magnetics for On Board Chargers and others”, were results from their research in miniaturization of the power electronics unit of energy converters were presented & discussed.

Magnetic components in power electronics are very often bulky and costly, handmade and not strait forward to cool. Using windings manufactured in PCB technology with ferrite cores is an alternative, but it comes along with some challenges, which were presented during the tutorial. The example of a 22kW On Board Charger (OBC) developed at Fraunhofer IZM with only planar magnetics was used to explain requirements and opportunities for these components. It consists of a 1/3-phase PFC part and a DC/DC-converter for galvanic isolation. The tutorial was organized in three sessions:

a. Electromagnetic Effects in Planar Magnetics

b. Planar Magnetics for On Board Chargers – PFC inductor

c. Planar Magnetics for On Board Chargers – DC/DC converter

About 20 people participated in the tutorial with high interest and positive feedback. Further updates on technological improvements will be shared, promising cost-effective manufacturing of these bulky components & devices by automatic assembly. Planar magnetics enable a significant volume shrinkage of power electronics, saving material, cost and energy while driving the electrification of vehicle fleets forward.